how to draw a 3d gear

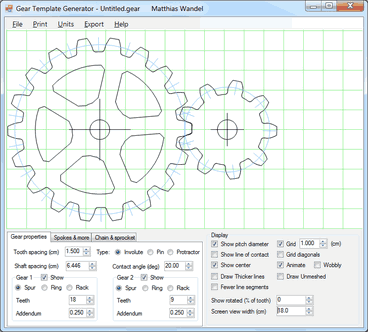

| Gear template generator helpThe gear template generator is a program to calculate and printgear shapes for anfractuous spur and pinwheel gearing. |

Gear ratio

I have had numerous requests to brand the gear program display the gear ratio. The reason the program does not explicitly brandish the gear ratio is that the gear ratio is whatever y'all enter. For example, if y'all take a tooth count of 7 and 12, the gear ratio is vii:12. That is to say, the 7-molar gear will turn 12 times for every 7 turns of the 12-tooth gear. Similarly, a 10-tooth with a thirty-tooth gear will accept a gear ratio of thirty:ten, which can too be expressed as 3:one.Compounded gear rations (more ii gears)

The gear program will show two gears and then yous can see how the gears mesh. Gears simply mesh ii at a time. If you demand to pattern a gear railroad train with more than two gears, you lot need to determine what gear pairs you need, and then use the gear program to generate the gears. Working out compound gear ratios is not something the gear programme will practise for you, just the question comes upwardly often enough that information technology makes sense to explicate here.

For example, if you want a one:10 reduction, but you lot don't want a gear smaller than ix teeth (smaller gears tin run rough) y'all could make a 9 and a 90 tooth gear. Only 90 tooth is a very large gear. Instead, you could brand a 10:30 reduction, followed past a nine:30 reduction. Multiplying those together will give you lot 90:900, which is a one:10 ratio. How to come up with these numbers? See beneath.

Example: designing a 1:12 reduction for a clock

If you want to build a clock, you volition need a final 1:12 reduction. Lets say minimum seven teeth, so limited it as 7:84. At present imagine we put a 24 molar gear betwixt the 7 and the 84. The seven:84 ratio is still intact. And then nosotros have vii:24 followed by 24:84. Lets divide the number of teeth on 24:84 pair by 3 (this won't change the ratio), then we have 8:28. And so a 7:24 and 8:28 pair volition requite the desired reduction. To cheque, multiply out: 7x8:24x28 is 56:672, Divide both sides by 56 gives i:12.

However, if the teeth of both pairs are the same size, the 7:24, having fewer teeth, volition have a smaller shaft spacing than the 8:28. Merely you can just enter the shaft spacing, and the gear program will suit the gear molar size appropriately, and so the 8:28 pair will have slightly smaller teeth.

More about gear ratios

Gear type and backdrop

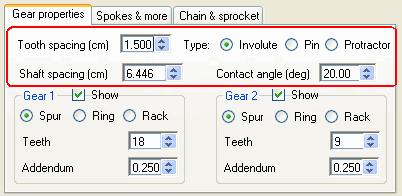

Tooth spacing

Specifies the centre to centre molar spacing, every bit measured along the gear's pitch bore.

Type

This selects what blazon of gear teeth to draw. The gear's teeth tin can be spur, pinwheel, or protractor.

Involute

This specifies anfractuous spur gears. Involute spur gears are the most commonly used type of gear. Any ii gears that have the same tooth spacing (or pitch) and the aforementioned contact bending (also known as pressure level angle) will mesh and run smoothly.

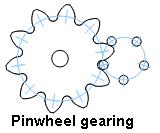

Pivot

For some applications, it is desirable that ane gear be comprised of just a ring of pins. Such gears are also known as "lantern" gears. The pins are typically held together by two discs on either side, and so that the whole structure could be said to look like a "lantern". Such a gear may or may not have a shaft passing through the middle of the pins.

The primary advantage of this type of gear is that it'southward possible to make gears with as few equally three teeth that will however run smoothly.

For pinwheel gearing, the gear on the correct will always be the pinwheel and the gear on the left volition always be cycloid shaped to mate with the pinwheel.

Protractor

Sometimes it's useful to be able to create a template that divides a circle into a specific number of intervals. For example, to carve up a circle into 23 equal parts with a protractor would exist irksome and error prone. Using this program you can print a template that divides the circle equally specified.

Shaft spacing

This field always displays the calculated shaft spacing value. The shaft spacing is the sum of the pitch radii of both gears. Pitch radius is calculated from the pitch circumference. Pitch circumference is equal to the number of teeth times the molar spacing.

You can also enter a new value in this field and the gear's tooth spacing will automatically be recalculated to produce the desired heart to center distance for the two gears.

Contact angle

This field specifies the contact angle, also known as pressure bending, for involute spur gears. Larger contact angles produce gears that accept more triangular looking teeth. Larger contact angles work meliorate for gears with a modest number of teeth, merely the overall consequence is lower efficiency due to college friction in the gear set.

This field is simply applicable for involute spur teeth and is hidden if other types of gear teeth are selected.

Pivot diameter

This field specifies the size of the pins for pinwheel gearing. This field is only applicable to pinwheel gearing and is subconscious if other types of gear teeth are selected.

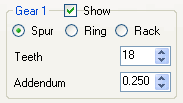

Gear properties

This section allows you to specify the parameters specific to each gear.

This section allows you to specify the parameters specific to each gear. Testify

Selects whether the gear is visible. Note that for pinwheel gears, the properties of the pinwheel bear on the shape of the mating gear, so even if the right gear is hidden, its properties notwithstanding bear on the gear on the left.

Spur

Selects a regular spur gear. That is, a round gear with teeth on the outside.

Ring

Selects a ring gear. A ring gear is a gear with teeth on the within. Ring mode can just exist selected if the other gear is a spur gear. Ring gears are useful when making planetary gear sets

Rack

Selects a "rack" type gear. A rack is substantially a gear that has been unwrapped. Rack and pinion fashion is simply currently available for involute tooth types.

Teeth

Specifies the number of gear teeth.

Odd shaped gears generated past setting the right side gear addendum to cypher.

Annex

Specifies the addendum of the teeth. The annex is how much the gear tooth protrudes outside its pitch diameter. It is specified relative to the tooth spacing. That is, a setting of 0.25 means that a molar's annex volition exist one quarter of the spacing, or near one-half of its width.The gear's dedendum (that is, how deep a cutting beyond the pitch circumvolve between teeth) is taken from the mating gear's annex. So to ready the dedendum of a gear, simply ready the respective addendum of the mating gear.

Note that cycloid gears don't apply the addendum parameters.

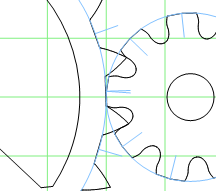

Spokes & more than tab

Diametric pitch

Some people prefer to employ diametric pitch, as opposed to tooth spacing (also known every bit circumferential pitch). Diametric pitch is equal to the gear'south tooth count divided past the pitch diameter, and then this number varies inversely with tooth size. Please note that version 2 and earlier of the gear generator calculated this as diameter per tooth (inverse of what it should be). You can enter a value in the diametric pitch, and the circumferential pitch on the main tab will automatically be updated.

Slop

The corporeality of full slop, play, or tolerance. With slop set to zero, the gears are printed and then that they fit exactly, with no tolerance for slop. Commonly, the width of the cut on the bandsaw or scroll saw will provide enough slop, but you can also add slop by setting this parameter.

Right angle thickness accommodate

When making 90 degree gearing, with your saw table tilted by the gear'southward contact angle, this field is used to tell the gear plan how thick your material is, and so that the teeth can exist "fattened" by the right corporeality then that the bevel cutting will upshot in gears of the right thickness. This parameter is ONLY used for involute spur gears.

Please see my article on correct bending gearing on how to use this. This characteristic was added for version 3.1.0 (Feb 2015). If y'all have an before version 3.0.x, click on "help" in the plan to go the latest version.

Pitch diameter

The pitch diameter is the diametric pitch times the number of teeth. The pitch diameter is useful for working out gear spacing. The ideal center to centre distance of a pair of gears is equal to the sum of the pitch diameters, divided by 2. Note that the shaft spacing in the "Gear properties" tab already shows the center to center altitude as "shaft spacing".

Overall bore

This displays the overall diameter of the gear, from tip to tip.

Spokes

Specifies the number of spokes. Only spur gears above a certain number of teeth are large enough to take spokes.

Shaft hole diameter

Specifies the shaft hole to draw. For pinwheel (lantern) gears, this specifies the size of the shaft in the middle of the pins. The gear teeth of the mating gear will be kept short enough and so as not to interfere with the key shaft. Specify zero to omit the centre shaft or shaft pigsty.

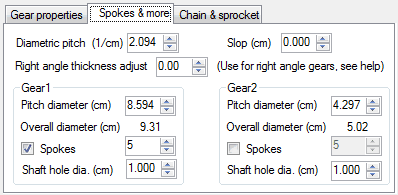

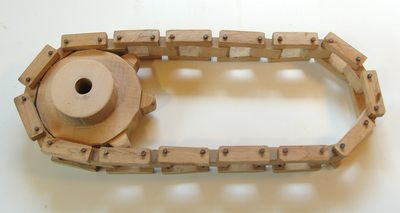

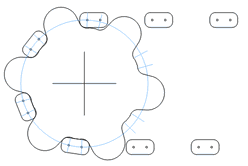

Concatenation & Sprocket manner

The gear template generator version ii.0 includes a "chain and sprocket" manner. This mode is intended to assistance in generating sprocket shapes for wooden block chains and roller chains. Chain & sprocket manner is turned on by selecting the "Chain & Sprocket" tab on the bottom left of the main window.

Chain & sprocket manner is turned on by selecting the "Chain & Sprocket" tab on the bottom left of the main window. The gear template generator can produce both block chain sprockets, and roller chain sprockets.

Nearly all modern metal drive chains, such as those used on bicycles, are of the "roller chain" variety. Roller chains accept a cylindrical roller on every pivot joint, with 2 sets of links on either side to join them together.

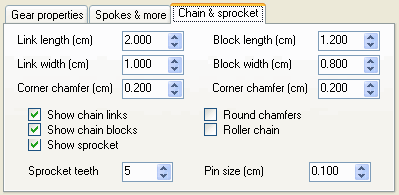

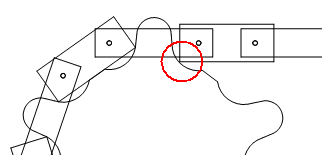

Cake chains are an older, obsolete mode of drive chain. Block bondage are much simpler to make, and lend themselves well to woods. In a block concatenation, the sprocket engages bocks in the middle of the chain. Each block has ii holes, to which the links on either side attach. An example utilise of a wooden block chain tin be seen in this tank thread vehicle

Cake chains are an older, obsolete mode of drive chain. Block bondage are much simpler to make, and lend themselves well to woods. In a block concatenation, the sprocket engages bocks in the middle of the chain. Each block has ii holes, to which the links on either side attach. An example utilise of a wooden block chain tin be seen in this tank thread vehicle

If the blocks of a cake chain are non rounded on the corners, and so the corners tend to scrape the sprocket where the chain engages and disengages the sprocket.

If the blocks of a cake chain are non rounded on the corners, and so the corners tend to scrape the sprocket where the chain engages and disengages the sprocket.

The gear template generator will generate sprocket shapes that make allowances for this "undercut" next to the teeth for this, but the sprockets are still somewhat ugly and inefficient.

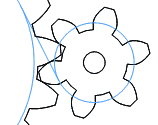

A much better solution is to put a bit of a round or chamfer on the edges of the chain blocks. The sprocket at left is very similar to the previous sprocket, only with blocks that have chamfered corners. Annotation that the teeth have much less undercut.

A much better solution is to put a bit of a round or chamfer on the edges of the chain blocks. The sprocket at left is very similar to the previous sprocket, only with blocks that have chamfered corners. Annotation that the teeth have much less undercut.

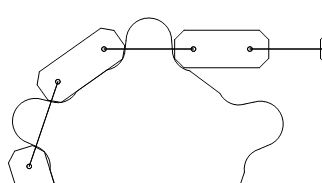

For clarity, I inverse the links to be very sparse, but the links practise non actually engage the sprocket, so only the link's length, not its actual shape contributes to the sprocket shape.

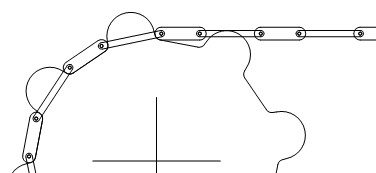

The gear generator tin can generate shapes for workable sprockets downwardly to iii teeth. However, these sprockets are inefficient and volition run very rough. If you use the "Breathing" function in the gear template generator, yous can see that the chain has quite a scrap of side-to-side move.

The gear generator tin can generate shapes for workable sprockets downwardly to iii teeth. However, these sprockets are inefficient and volition run very rough. If you use the "Breathing" function in the gear template generator, yous can see that the chain has quite a scrap of side-to-side move.

The shape of the teeth also doesn't engage the chain very well, as the teeth demand to be very sloped to allow the chain to engage and disengage the sprocket.

Sprockets with larger number of teeth will run much more than smoothly.

Sprockets with larger number of teeth will run much more than smoothly.

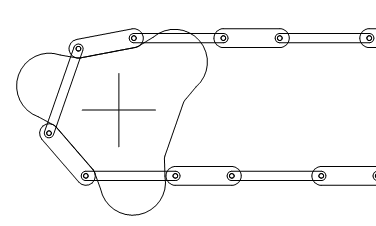

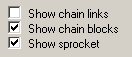

To better encounter how the chain meshes, parts of the chain and sprocket can exist hidden. The paradigm at left, for case, has the chain links subconscious. You can also hide the chain entirely. Hiding the chain is useful when making a printout of the sprocket template shape to use when cutting the sprocket out of plywood.

To better encounter how the chain meshes, parts of the chain and sprocket can exist hidden. The paradigm at left, for case, has the chain links subconscious. You can also hide the chain entirely. Hiding the chain is useful when making a printout of the sprocket template shape to use when cutting the sprocket out of plywood.

The epitome at left likewise has the "Show pitch diameter" turned on. The blue lines represent the pitch diameter, and the lines crossing it indicate the centers of the tooth undercut radii. If you lot have the right size drill, you can start by drilling out the undercut circles, which will make it easier to cut out the rest of the sprocket with a bandsaw

Specifying the chain dimensions

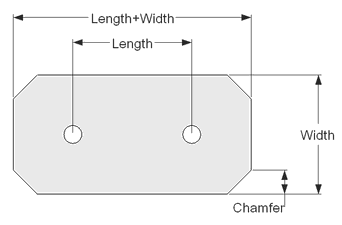

The shape of the sprocket teeth is generated based on the shape of the chain blocks, and the length of the chain links.

The shape of the sprocket teeth is generated based on the shape of the chain blocks, and the length of the chain links. The shape of the chain blocks and links is specified in terms of length and width. Please notation that the specified length is the length between the 2 holes. The program automatically adds some length to the link to permit for material around the holes.

An boosted parameter, "Chamfer" determines how much to remove from each corner of the blocks and links. If "Round chamfers" is selected, the chamfer is replaced by a round with a radius equal to the chamfer measure.

Display parameters

This role of the panel selects which aspects of a gear to brandish.

Prove pitch diameter

When selected, a circle is drawn indicating the gear'southward pitch diameter.

Show line of contact

For involute teeth, this shows the contact angle (pressure angle) and base radii of the two gears. If yous think of the base radii as being 2 spools, a point along a string unwound from the correct gear's base radius and wound onto the left gear's base radius would exactly follow the path along which both gears touch.

Testify eye

Bear witness a crosshair in the eye of each gear.

Describe thicker lines

Doubles the thickness of lines used to draw the gear, then that the lines show up better on printouts.

Draw unmeshed

If both gears fit on one folio, select this option to draw the gears separated so that when you print them, you can cut the two shapes out separately. Also useful for CAD exporting both gears at the same time.

Fewer line segments

Approximate the circular curves of the gears with fewer line segments. The difference is not noticeable at a glance, merely when exporting and importing into other programs, some programs accept difficulty with the number of line segments that the gear program creates.

Grid

Draw a grid. The filigree is useful for getting a sense of scale, for checking that a printout was scaled correctly, and to help align multiple pages together when pasting together multi-folio printouts.

Grid diagonals

Draw diagonal lines on the filigree. Diagonal lines are very useful to help align the sheets of a multi-page printout when gluing the pieces of paper together. The diagonals grids piece of work then well, I later wrote BigPrint to allow other types of images to be pasted together this manner.

Animate

Slowly turn the gears. This allows you lot to examine how the gears mesh. Notation that spur gears with less than 10 teeth and low contact angles will often cause interference. For gears with very few teeth, try pinwheel gears.

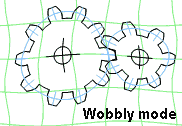

Wobbly

I implemented "wobbly mode" for the evaluation version of the program. The eval version can do everything the full version tin exercise, but all output is distorted. The distorted gears would not piece of work in real life.

I found the distorted "wobbly mode" fun to watch, so I have added this "feature" as an option to the full version also, just for fun.

Evidence rotated

This field causes the gears to be displayed rotated. The angle is specified as one hundredths of a tooth. Specifying 25, for instance, will cause the gears to be rotated by one quarter tooth interval.

This feature is useful if you want to check that spur gears mesh without interference. It'southward specially useful if you use the upwardly/down buttons, and zoom in on the meshing indicate by reducing the value of the "screen view width" field.

Screen view width

This field indicates how broad an surface area the screen represents. This value defaults to 20 cm, or about the width of the printable region on a normal piece of paper.

Note that this value is in whatever units you chose. If you alter the units to "inches" then the visible region would change to 20 inches, along with all other dimensions. The display would not change, but when you lot print it, it will now exist much larger as it's now sized in inches.

Saving

The parameters for a gear can be saved in a file for after reloading. The parameters are simply stored in a text file. If a file called "default.gear" exists in the same directory as the program, it will be loaded automatically when the program starts.Units

Units can be selected to exist inches, centimeters or millimeters. Note that the displayed gear'due south size does non alter if the units are changed. A gear that is 10 cm across, when you change the units to inches, volition now exist 10 inches across. The screen width would likewise change from 20 cm to xx inches. However, on press or exporting, the gears will be scaled accordingly. Note, however, that on importing DXF, the units are not specified within the file. Typically, 1 must betoken to the importing plan what units are represented in the file.Printing

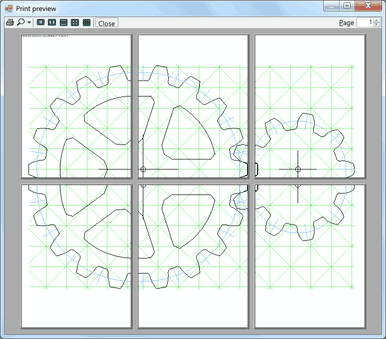

The gear template generator is able to impress gears that span many pages. If a gear does not fit onto a single page, then the gear is divide across multiple pages to be printed then glued together.

The gear template generator is able to impress gears that span many pages. If a gear does not fit onto a single page, then the gear is divide across multiple pages to be printed then glued together. Grid lines, specially when combined with diagonal grid lines, are very useful to help precisely align the pages when gluing them together.

It'southward advisable to exercise a print preview before press your gears. The dimensions you lot have specified might consequence in gears that span a surprisingly large number of pages.

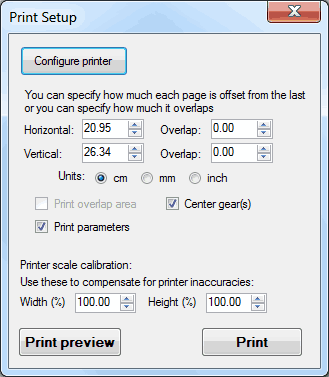

Printing parameters

Printer calibration calibration

You lot may find that your printer prints just slightly larger or smaller than it should, especially if your printer is a laser printer. If you find that 10 grid lines of a i centimeter filigree are really x.1 cm horizontally, you lot tin can recoup past setting the width scale to 99%. If you switch to "landscape" orientation, the "width" is actually the length. The labels adjust to reflect this.

Horizontal / vertical / overlap

If you lot print gears that bridge multiple pages, the gears are printed with no overlap past default. You may adopt to have a slight amount of overlap from folio to page to give you more than confidence in aligning the pages. You can either enter the overlap, or yous tin enter the spacing of the pages. Annotation that the spacing and size of the pages always total up to the printable area on a folio.

Y'all may also notice that its quite piece of cake to align the pages even without overlap when filigree diagonals are enabled.

Impress overlap area

You tin can select whether to print in the overlapped expanse. This choice is merely enabled if an actual overlap is selected using the horizontal/vertical/overlap fields.

Center gears

Normally, the gears are in the peak left of the folio, or group of pages. If y'all check this, the gears volition be centered on the page, or group of pages.

Impress parameters

If checked, the bodily gear parameters will be printed on the top left of the folio.

Exporting

When exporting to a file, everything that is drawn on the screen is exported. This included both gears, besides as any center and filigree lines you may have turned on. Information technology'southward recommended that you plow off everything but ane gear and its center crosshair before exporting. Otherwise, information technology can exist difficult to carve up the gears from the grid in whatever program y'all are importing into.No printer pagination volition be applied to consign.

in SketchUp

DXF (with poylylines)

Most CAD programs tin import DXF files. The gear template generator's DXF export is relatively simplistic and just two dimensional, but it will get the shapes into your CAD programme.The DXF consign does not include units. Programs that import DXF typically allow yous to specify which units the DXF file actually uses. For example, if you used inches to design your gear, but the importing plan assumes the units are millimeters, the imported gear will exist much smaller than y'all await.

Please notation that DXF export with polylines for version iii.0.x is less than perfect and that AutoCad volition not successfully import this. Version 3.one improves DXF polyline export and works with AutoCad. Click on "aid" in your program to update.

DXF (basic DXF)

DXF is a very difficult to figure out format, and the DXF exported past the gear template generator may not exist uniform with all programs. If the "with polylines" export does non work, try exporting as basic DXF. Basic DXF exports line segments merely. Unfortunately, this means some programs will not recognize the outline as a joined object.SketchUp

One of the most popular CAD programs among woodworkers is the free SketchUp. However, the free version of SketchUp does non handle DXF import. It does, withal, import data in "Collada" format. Considering then many people employ the free version of SketchUp, I implemented export to this format so that you can yet import gears into the gratuitous SketchUp. As CAD programs go, SketchUp is relatively piece of cake. But be warned. All CAD programs accept a steep learning curve.When y'all import a gear into SketchUp, it will be imported every bit nested objects. Keep opening the objects until you can select individual line segments of the gear outline. To plough the outline into a surface that can be extruded, describe a rectangle around the whole outline, and then delete the outline of the rectangle. If your gear has spoke and centre holes, select these with a double click, copy them, delete them, and so paste them in place. After that, y'all volition be able to delete the surface inside the spoke holes. I don't call back SketchUp works as well as they say it should in this particular regard, merely the in a higher place procedure has worked for me.

HPGL

HPGL stands for "Hewlett Packard Graphics Language". It is the format used by the old HP plotters. Nobody uses plotters anymore, but the format is fairly straightforward and various pieces of software however know how to import and export graphics in this format.

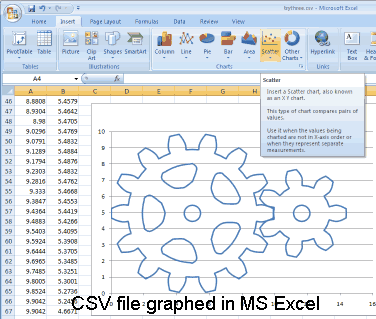

CSV (for spreadsheet)

CSV (Comma Separated Values) is the simplest form of export, consisting of but 2 columns of numbers, plus some annotation. This format can be loaded into spreadsheets such as Excel. You can brandish the gears as a graph in Excel by selecting the 2 columns of numbers and generating an X-Y besprinkle graph from the data.Displaying gears in a spreadsheet is not especially useful, but it's a good starting point if yous wish to manipulate the X-Y points in some way for your own purposes.

Paradigm (bitmap)

Exports the image as a bitmap (BMP, Jpeg, or PNG). A window will pop up allowing you to specify how many pixels per size unit (pixels per inch, per centimeter or per millimeter), and whether antialiasing (line smoothing) is turned on.If you need to create a PDF for printing across multiple pages on another printer, the best way to proceed is to print to a file. To print to a file, go to "configure printer" under impress setup, and select "Microsoft XPS document..." as the printer. And then impress. Windows will prompt you to specify a file to impress to. Then upload the XPS file to http://www.xps2pdf.org/ to convert it to a PDF file. Note that this pull a fast one on works with any program that can impress to a printer. No need to install special software on your computer to create PDF files. There are also "printer drivers" available on the internet that allow you to impress straight to a PDF file on your computer, such as the complimentary Bullzip PDF printer driver , but printing to XPS and and so converting doesn't crave any actress software installation.

SVG

SVG stands for scalable vector graphics. Some newer laser cutters and CNC routers are able to import SVG. SVG was intended for screen graphics, and is sized in pixels. Y'all take to enter how many "pixels" per unit of measurement your importing program expects. Otherwise, the object may not come up out the correct size. SVG export was added with version three.one.one, March 2015.

Whatsoever other questions?

If you accept whatever questions almost the gear template generator that this Assistance doesn't answer, experience free to email. Feedback is always appreciated.My e-mail address is:

More virtually the Gear template generator

Source: https://woodgears.ca/gear/help3/index.html

Enregistrer un commentaire for "how to draw a 3d gear"